How Cemetery Monuments are Crafted

Monuments: From the Ground Up

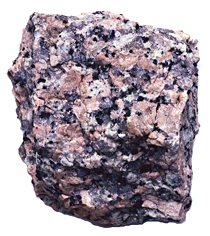

Monuments come from humble roots. More commonly used than marble, granite is the most commonly used stone in cemetery monument creation. Granite is a naturally occurring stone that starts as molten rock, or lava when found above ground. The type of granite is determined by a few factors. The main factor is the concentration of the quartz, feldspar, mica, and amphibole minerals present. A varying amount of these minerals results in granite of different styles or colors. In addition, the speed the granite cools and hardens at also determines the coarseness of the grain. This grain is the namesake of granite, which derives from the Latin word granum, meaning grain.

Before granite is ready to be refined and designed into a headstone, footmarker, mausoleum, etc, it must first be excavated from the ground. To excavate the granite for use in a memorial or monument, it is quarried into blocks. This is done with the use of a jet burner, essentially a small rocket motor that burns fuel oil and oxygen. The flame leaves the burner over 450% faster than the speed of sound and burns at over 2500 degrees Fahrenheit. This flame acts like a fiery knife that cuts through the granite, forming channels for what while become the rear end of the granite block.

The quarrier then drills holes into the future monument, and loads them with black blasting powder. As pictured above, when the explosive detonates, it does so powerfully, and lifts the block from the surrounding stone. Weighing as much as 10 tons, the block is loaded onto a truck to a manufacturing plant.

Manufacturing a Monument

The blocks prepared at the quarry are naturally too large, too heavy, and too rough to be shaped and designed by your monument builder. Instead, it first makes a pit stop at a manufacturing plant. At this plant, the block from the quarry is cut into slabs measuring at anywhere from 3 to 12+ inches thick with a diamond rotary saw. These slabs are carted off to a polishing machine that shines granite into it’s usual, mirror like sheen that are characteristic of monuments and memorials. Cut a final time in a guillotine into smaller, workable slabs of varying sizes, the granite slabs are then finished and trimmed by trained craftsmen. Depending on how the monument stone is ordered, it is sometimes given a final polish or left rough.

The Final Steps

Quarried, cut, and polished, the granite is finally ready to be worked and designed by a cemetery monument builder. Sketched, designed, and stenciled, most often by hand, the monument builder takes an artisan level of care to sandblast the monument to perfection. Designs must be flawless- they are, after all, a final remnant to embody the spirit of a deceased loved one. At St. Charles, we are proud to declare that our builders are among the most caring available. Different textures and finishes can be applied to give every monument the most unique appearance. From here, the monument is cleaned and polished a final time, and is ready to be set in the cemetery.

If you’re interested in learning more about the production of monuments, or are ready to move forward with your monument purchase process, don’t hesitate to contact us now.